Smart Apparel

eRav Smart Apparel is an ERP system specifically developed for the apparel industry that aims to provide in-depth statistics and information that encourage data-driven decision-making approaches. The system supports the undertaking of complex manufacturing orders, even in instances where limited resources may be available.

What sets eRav Smart Apparel aside from similar software is the way it integrates innovations in the technology industry into the system and makes them work for the apparel industry. While many ERP and CRM systems are available in the market, few compare to the consistent innovation brought forward by eRav Smart Apparel. Furthermore, eRav Smart Apparel’s management functions can easily be done through the mobile applications, dramatically increasing its accessibility.

All these features combine to create a definitive ERP system for the apparel industry.

Here is how eRav Smart Apparel integrates industry innovations into its system and acts as a proactive software-based solution for any and all garment manufacturing management requirements.

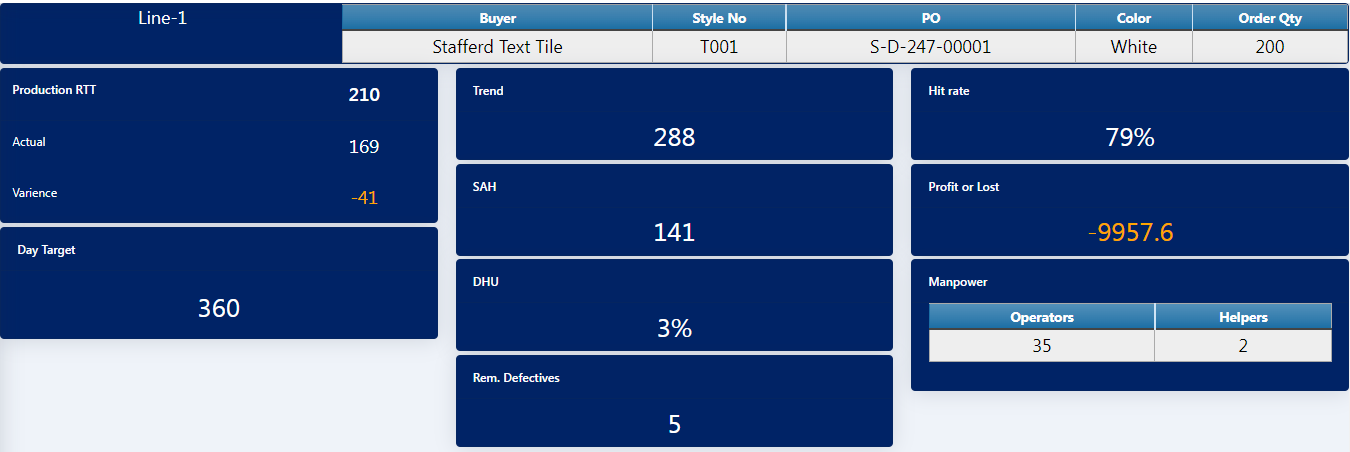

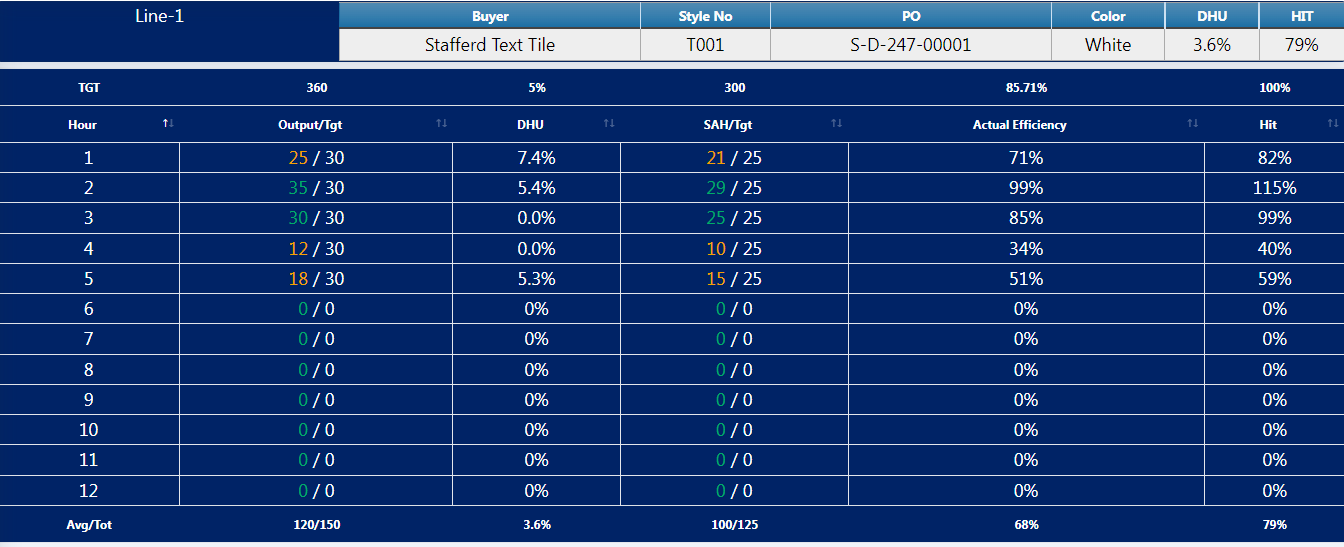

Production Monitoring (Real Time Data Monitoring)

eRav Smart Apparel provides comprehensive statistics and information that encourage well-informed, data-driven decision-making processes for organisations. Some pools of data that are extracted from the production monitoring process are as follows:

- Sales Orders

- Actual Production and Cutting Output

- Line Input

- Line Output

- Shipment

- Gate pass preparation

- Reports

Style Development and Preorder Processing (BOM Finalize)

eRav Smart Apparel’s advanced preorder processing capabilities support cross-checks with all possible variations of the production requirement, allowing smooth production order execution.

Preorder processing also accumulates all available data from the system to create finite solutions based on the exact requirements of a new order. As the Bill of Materials is a prime indicator of the overall profitability of a production order, finalizing it is made simpler than ever with this system.

Data on tech packs, sketches and received BOMs are stored in the system along with sample preparation and BOM updates, and costing details. Once these are finalized, the system creates a timeline for sample preparation and allows approval monitoring. It also offers a real-time buyer feedback monitoring system.

Inventory Management

eRav Smart Apparel’s inventory control system provides accurate estimates based on previously processed orders along with the margin of waste.

Inventory control provides material estimates before initiating a manufacturing order by utilizing data from the existing inventory of product categories and multiple subcategories. The system can be integrated into multiple warehouses and factories. The feature-rich inventory management system will ensure that stocks are never lacking, whether it is for existing production orders or newer ones.

Developed with the guidance of industry experts, this system is functional in all types and sizes of organizations in the industry.

Cutting Management

eRav Smart Apparel’s cutting management module assists in streamlining all processes related to cutting in the production process. Marker creation, fabric layer management, fabric roll management, fabric usage management, and bundling can all be monitored and managed through this system.

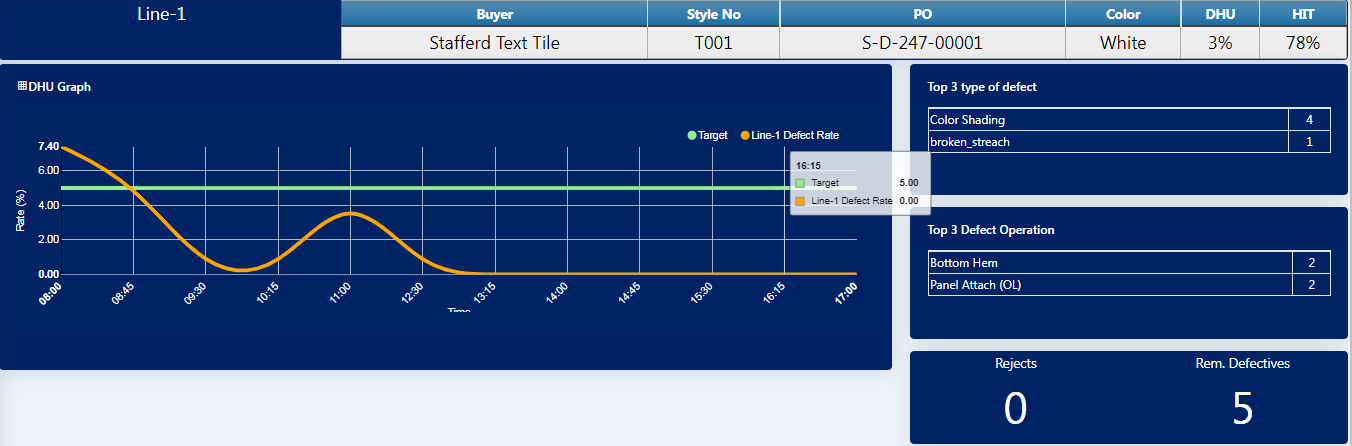

QA Analysis

Quality is of paramount importance in any type of business, and it holds true in the apparel industry. eRav Smart Apparel offers a dedicated feature that allows organizations to ensure that their quality standards are met in every batch produced.

A systematic reporting system has the capability to understand specific Pass/Fail conditions for QA analysis, and the system offers extensive control over all quality tests and provides detailed information for understanding the underlying reasons contributing to QA success. Acceptancy Quality Level reports such as Inline, Prefinal, and Final QC reports are also generated by the system. These functions are all available through the mobile application.

Line Details

Skill Matrix

eRav Smart Apparel’s innovative Skill Matrix system has the ability to identify the skill levels and productivity of each employee, along with cross capabilities in the production chain. This information can be used to ensure that all employees are capable and competent in using equipment and knowledgeable of the production technologies the organization utilizes.

One major tangible advantage Skill Matrix provides is the evaluation report of individual employees. The management can use these reports to identify potential training requirements and opportunities to redirect labor into a different part of the production chain. Such initiatives will boost efficiency and deliver better outputs.

Downtime/Lost Time Analysis

Smart Apparel is equipped with a sophisticated Lost Time Analysis calculation methodology that allows the organization to understand and eliminate the factors contributing to the underperformance of the organization’s productivity.

Calculating the Lost Time has become a tedious and complex activity whilst Smart Apparel emphasizes accurate calculation with the click of a button. Considering various factors that are contributing to the Lost Time of productivity, this calculation is a crucial element in the delivery of production batches and also the consistency of delivery.

KANBAN

Deriving from the Japanese terminology and the understanding of Lean Manufacturing and Just-In-Time Manufacturing (JIT), Kanban is one of the methods to achieve JIT. Smart Apparel is designed with strong roots in the Kanban system which demonstrates key performance indicators that are ideal to sustain efficient inventory levels and effective logistics control systems.

The Goal of the Kanban system is to minimize excess inventory buildup at any point in the production. Limits on the number of items at the supply points of the production cycle are established and controlled to reduce inventory tied up. Hence, utilizing Smart Apparel will ensure minimum quantities required are in place and would immediately inform the management if any measures are exceeded.

Kanban system is based around the sustainability of the critical factors of operation and the critical activity of the production. It thrives on understanding the necessary capacities of each resource and ensures that there is never a bottleneck created that would hinder the production and the expected outcome of quality and quantity. Smart Apparel is designed to ensure that Kanban strategies and tactics are applied in every aspect of the production facility and the manufacturing logistics. The system provides the management with the decision making KPIs that would ensure outstanding management innovation. The critical operation is identified and accounted for with sophisticated forecasts and numerical with the mathematical engineering behind Smart Apparel to ensure that the organization is operating at optimum capacity.

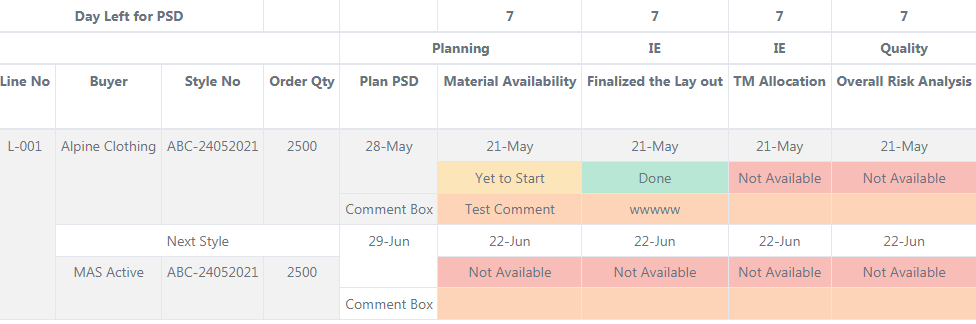

QCO - Quick Change Over

Smart Apparel allows you to manage QCO Process Effectively. When shifting from one design to another the management must make effective and efficient decisions that will minimize the Bucket Loss during the change.

The Quick Change Over – QCO process of Smart Apparel, standardizes the work process and utilizes various strategies in problem-solving, error proofing, & workload balancing. The Function gives you real-time information as to the actual output against the plan.

Also, the system is designed to co-operating various management strategies such as KANBAN & Kaizen & Visual Display of data; the user can identify key elements in the process and plan accordingly.

Furthermore, the system identifies the skills, capacities & output of each resource and enables quality decision making. Over time, the user identifies the key indicators during QCO with the help of Smart Apparel to proactively plan future sales planning.

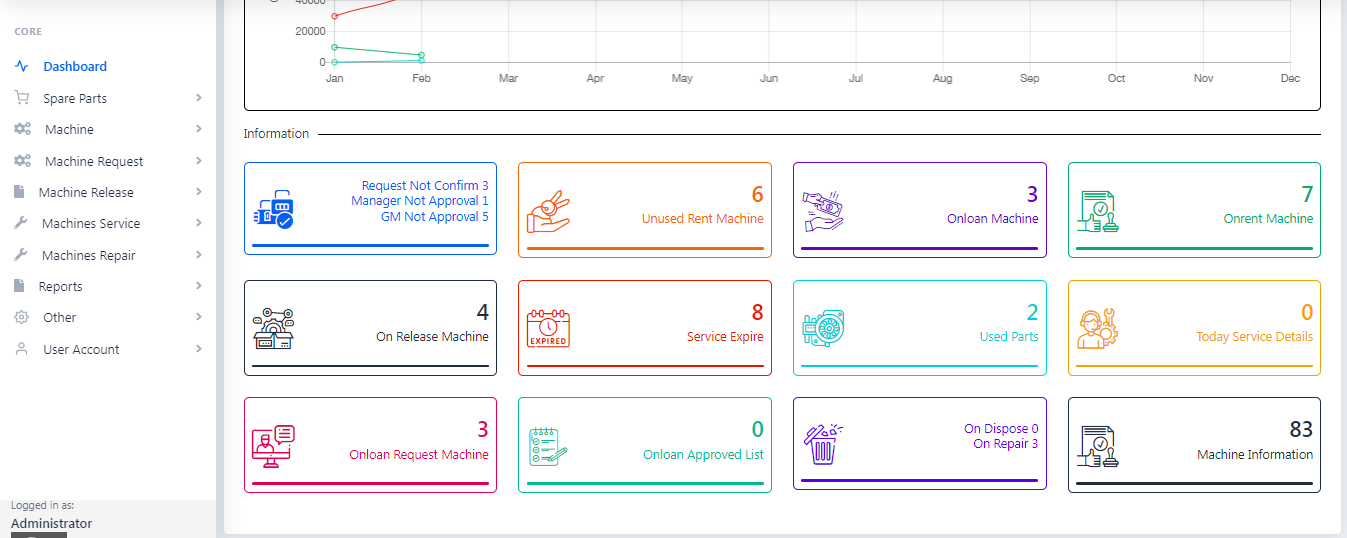

Machine Management

eRav Smart Apparel’s dynamic data collection capabilities track depreciation, forecasted output, and potential breakdowns of all the existing machinery of the manufacturing and supply chain arm of the organization.

This information is tracked using digital mapping of the output. From the ownership of the machines and existing rented machines and due dates to the cost incurred on repairs per machine, per day. Machine output can be tracked in real-time, for all machines in the manufacturing process across multiple locations. This allows the identification of underperforming or under-utilized machines. In addition, with the use of IoT devices, machine run-time (hours) can also be recorded.

eRav Smart Apparel’s machine management system has been tested on multiple models and makes of machinery, and the accuracy of information provided across the board has been truly remarkable

Workstudy Planner

The Workstudy Planner is a combination of three features in the eRav Smart Apparel kit. Namely, Skill Matrix, Machine Management, and Style Development. This compilation of features allows for an ultra-productive work environment, where pre-production requirements are met optimally and labor and machinery are used at ideal capacities for optimal points in the manufacturing process.

FAQs

eRav Smart Apparel consists of 11 modules:

- Production Monitoring

- Style Development and Preorder Processing

- Inventory Management

- Cutting Management

- QA Analysis

- Skill Matrix

- Downtime/ Lost Time Analysis

- KANBAN

- Quick Change Over

- Machine Management

- Workstudy Planner

Additionally, an accounting module that provides customisable, comprehensive accounting reports is also available.

Set up timeframe can vary from a few weeks up to a few months depending on the nature of the business, number of suppliers, locations, and users, chosen modules, and the extent of customisation necessary from us.

Once we are aware of your requirement, we can provide a more solid timeframe estimate.

No, you can customise the amount of modules you need. You can integrate additional modules into the system as required.

We are always prepared to provide support if and when it is required. Our customer service personnel are always there for you.

Our accounting functions can actually serve the same purpose as any accouting software, which means you do not need to invest in a separate one. It also has a simple import/ export functionality, so you extract information into Excel too if necessary.

Possibly, our modules are a perfect fit for a multitude of industries. However, we also offer a range of other products that may better suit your industry